🔬 Case Studies of Our Projects

1️⃣ Material Handling

Design and analysis of cranes, lifting mechanisms, and support structures ensuring safety, stability, and code compliance.

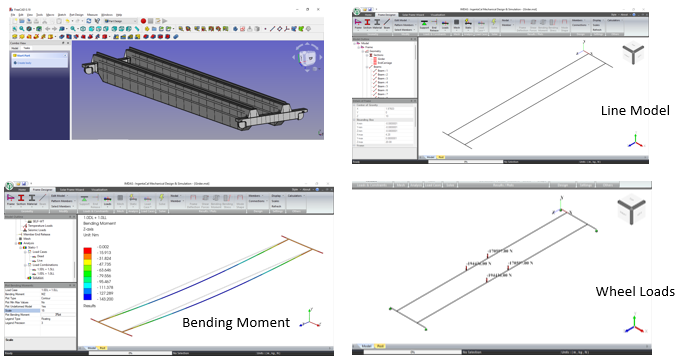

EOT Crane Analysis

We performed a complete structural design and analysis of a 45-ton Electric Overhead Travelling (EOT) crane, covering both the box girder and trolley assembly. The project involved detailed finite element modeling, load case development as per IS 800 - 2007 crane design standard, and evaluation of bending stresses and deflection.

The analysis ensured safe lifting performance under static, dynamic, and impact loading, and validated the box girder and trolley components for strength, stiffness, weld sizing, and serviceability requirements. Optimized design recommendations were delivered to enhance reliability and reduce material weight.

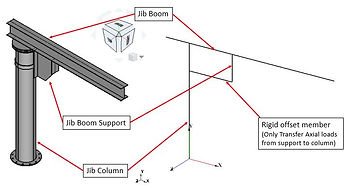

Jib Crane Design Validation

In this project , design calculation of 4T Jib crane is performed as per guidelines of

IS 15419, IS-807 and IS-800:2007 to validate the structural design of all

members.

As per IS 15419, IS-807 cl.8.4 & IS-800:2007 cl.5.3.3, acceptability of a design

is confirmed by satisfying the relevant Load Cases and Combinations.

2️⃣ Oil & Gas

Finite element analysis of pressure vessels with nozzles to evaluate stress distribution, nozzle loads, and reinforcement adequacy under internal pressure and external loading conditions.

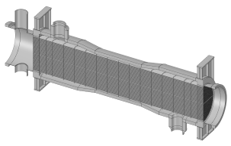

Pressure Vessel Analysis

Finite element analysis of pressure vessels with nozzles to evaluate stress distribution, nozzle loads, and reinforcement adequacy under internal pressure and external loading conditions.

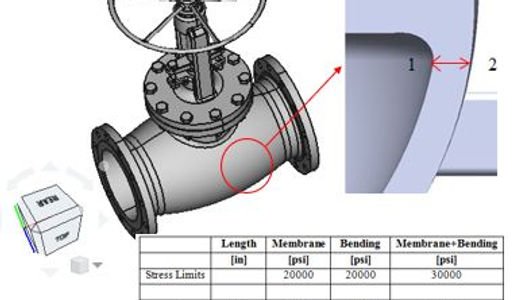

FEA Analysis of Globe Valve As per ASME Design By Analysis Method

In this project , Linear static analysis of 20’’ globe valve is performed to verify structural integrity of proposed design.

FEA Analyses is conducted on the valve Body/Bonnet assembly to assess the strength of the body, bonnet and bolts in accordance with ASME Sec VIII Div.2 part 5 cl 5.2.2.1 Elastic Stress Analysis method.

Stress linearization is done to compute the membrane, membrane + bending and peak components of stresses which are compared with allowable stresses to assess protection against plastic collapse.

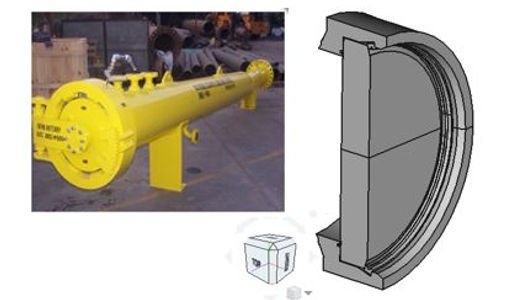

FEA Analysis of Quick Opening Closure As per ASME Design By Analysis Method.

Quick opening closures (QOC) are engineered doors with quick action mechanism, used for quickly accessing pipelines or pressure vessels. These closures are designed in accordance with ASME Sec VIII Div. 1 requirements.

Elastic-Plastic FE analysis is performed as per ASME Sec VIII-2 part 5 cl 5.2.4 to validate the design of 46” 600# QOC for protection against plastic collapse and local material failure.

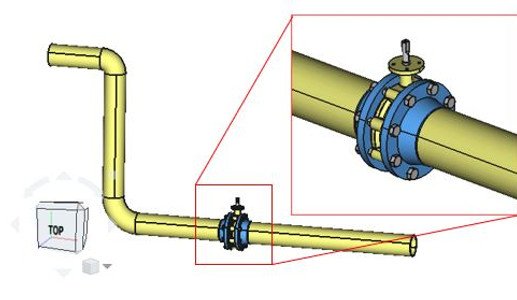

Seismic Analysis of Butterfly Valve As per ASME Sec 3 ND-3500

In this project we have performed seismic evaluation of valve used in nuclear power plant for structural integrity assessment.

The assessment has been done in accordance of ASME SEC III ND-3500.

The valve is classified as Class-3 equipment.

The normal operating loads considered for analysis include dead weight, pressure, temperature and nozzle loads. Seismic analysis is carried out for two levels of earthquake namely Operating Basis Earthquake (OBE) and Safe Shutdown Earthquake (SSE).It is required that the valves continue to perform the intended function during and after earthquake.

All loads are combined for different service levels and qualification as per ASME B&PV, Sec III. Stress levels determined by FEA are compared with stress limits as per codes to determine structural integrity of the valve.

3️⃣ Structural Engineering

Structural design and verification of industrial frames, mezzanines, and pre-engineered buildings using finite element methods.

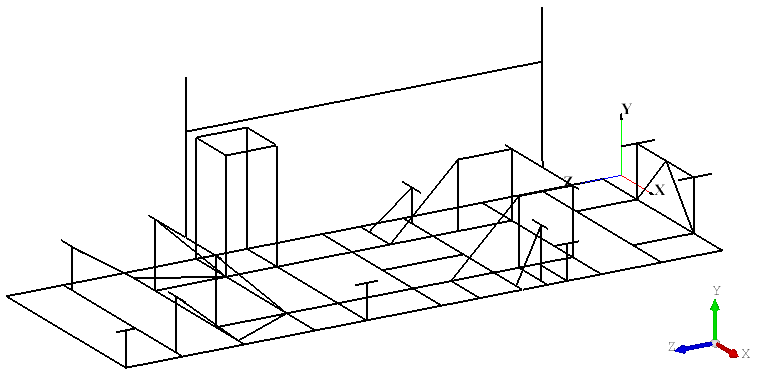

Steel Structure FEA

Finite element analysis of steel structures under combined dead, live, wind, and seismic loads to verify strength, stability, and serviceability in accordance with applicable design codes.

Skid Frame Analysis

Structural analysis and design of skid frames subjected to operating, transportation, wind, and seismic loads. Member forces, stresses, and deflections are evaluated using IS 800 and relevant standards.

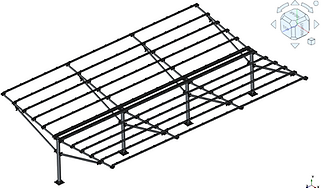

Carport Structure

Wind and dead load analysis of Carport Structure

Assesses member forces and deflections to ensure compliance with IS 800 requirements.